Quality expectations and the range of safety requirements that you must achieve become more complex every day. When your product fails to meet your quality specifications for market acceptance, the result can be loss of good will, product and revenues, delayed shipments, wasted materials, and the potential risk of a product recall. Deen Inspections has the right systems, processes and procedures to help you meet the requirements and to deliver quality products in a timely manner.

The pre-production inspection (PPI) is a type of quality control inspection conducted before the production process begins to assess the quantity and quality of the raw materials and components, and whether they are in conformity with product specifications. Prior to production, our inspector arrives at the factory.

Raw materials and accessories check:

Our inspector checks the raw materials and components required for

production.

Inspection report:

Our inspector issues a report which documents the findings and includes

pictures.

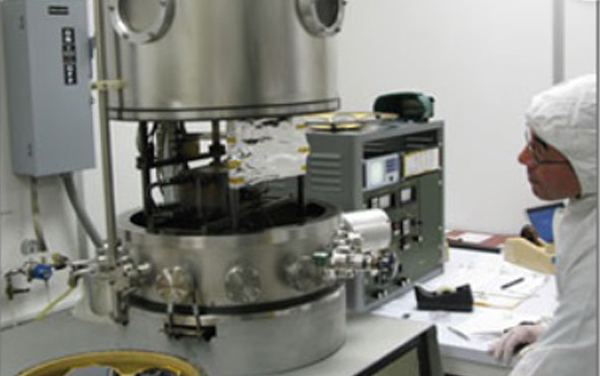

During production inspection (DPI) or otherwise known as DUPRO, is a quality control inspection conducted while production is underway, and is especially good for products that are in continuous production, that have strict requirements for on-time shipments and as a follow-up when quality issues are found prior to manufacturing during a pre-production inspection. At each stage of the production process, our inspectors will produce a full and detailed inspection report, together with supporting pictures to provide you will the comprehensive information and data you need.

A DPI allows us to detect errors that might lead to a non-conforming product before production is completed. Quality engineers verify that the manufacturing processes are reliable and consistent, and that the products coming off the production line are in accordance with your requirements.

The pre-shipment inspection (PSI) is one of many types of quality control inspections conducted by Deen Inspections. It is an important step in the quality control process and is the method for checking the quality of goods before they are shipped. Pre-shipment inspection (or psi- inspections) ensures that production complies with specifications of the buyer and/or the terms of a purchase order or letter of credit. This inspection is conducted on finished products when at least 80% of the order has been packed for shipping. This inspection is done according to standard acceptable quality limits (AQL) specs for the product.

At the end of the supply chain, we offer container loading supervision at the factory or majors ports to ensure safe transportation and delivery of the goods to their destination. This quality control point involves supervising the loading process, monitoring the quantity of the packed goods, checking the storage and condition of the container before and after closure and whether the goods are correctly handled/placed into the shipping containers.

Whatever the scope or complexity of your project, you can count on the accuracy and reliability of Deen Inspections with the most competitive pricing, fastest delivery times in the industry, and the support of a single point of contact for all your testing projects; this personalized approach has established us as one of the most respected labs in China. Through our associated professional consumer product testing laboratory, you can rely on us to test for compliance against RoHS, REACH, ASTM, Ca Prop 65, EN 71, to name a few.

Deen Inspections's network of quality professionals extends to those interested in assisting with short-term rework and/or sort projects ranging in complexity. Our local network is ready to be deployed directly at your supplier's site, or at your location. Quality inspectors use Deen Inspections 's standard report forms, or we can use those provided by the client. Service reports with detailed photos are provided, and all information available online within 24 hours of completion.